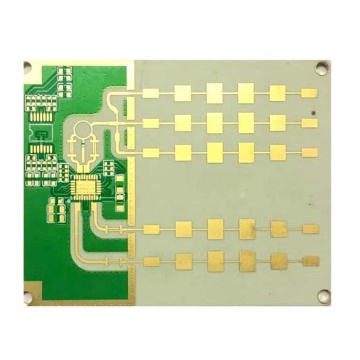

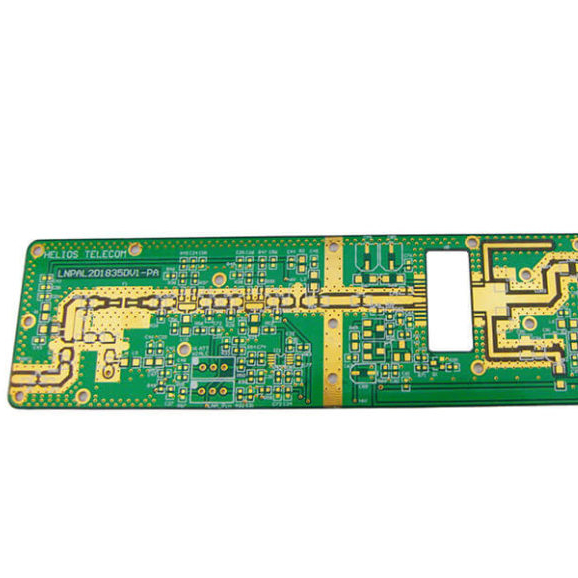

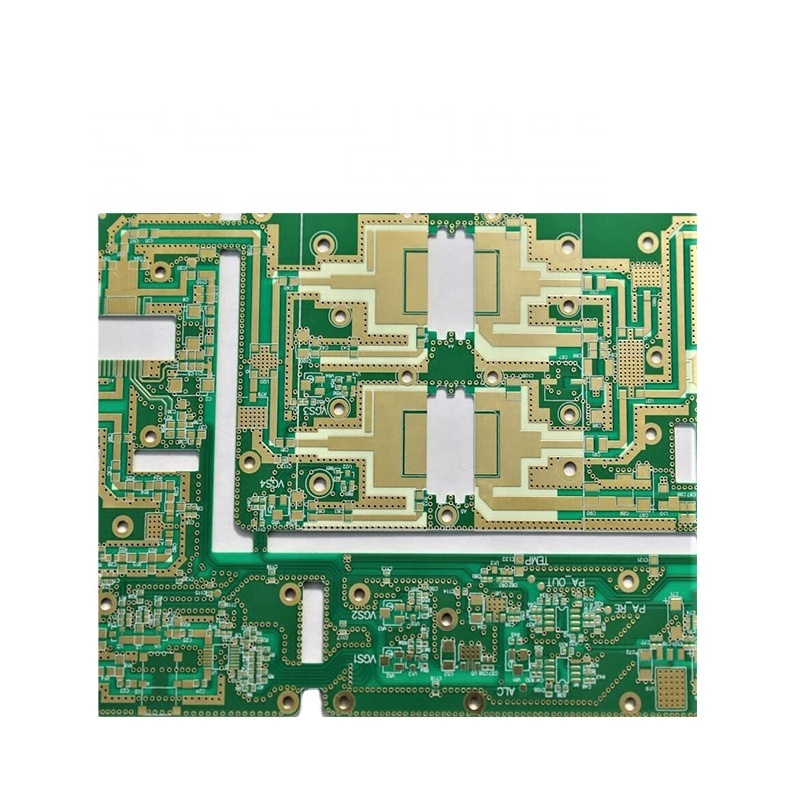

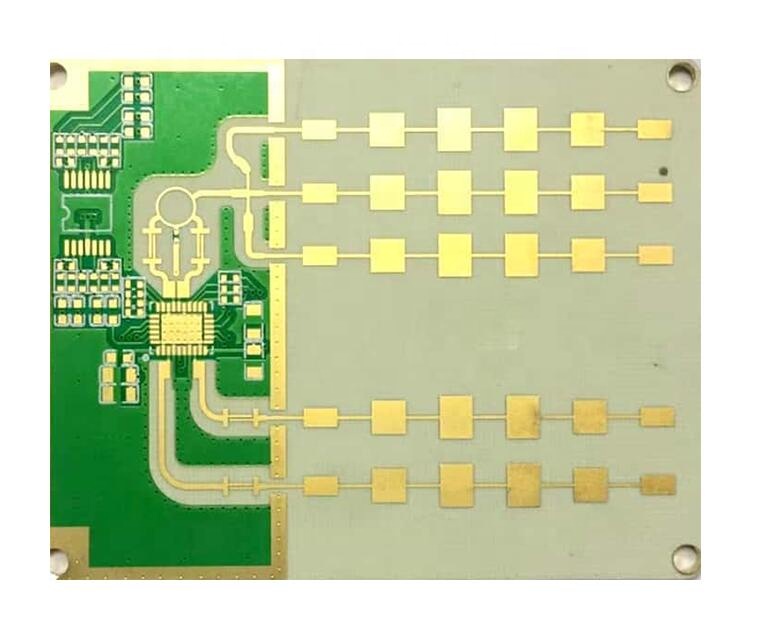

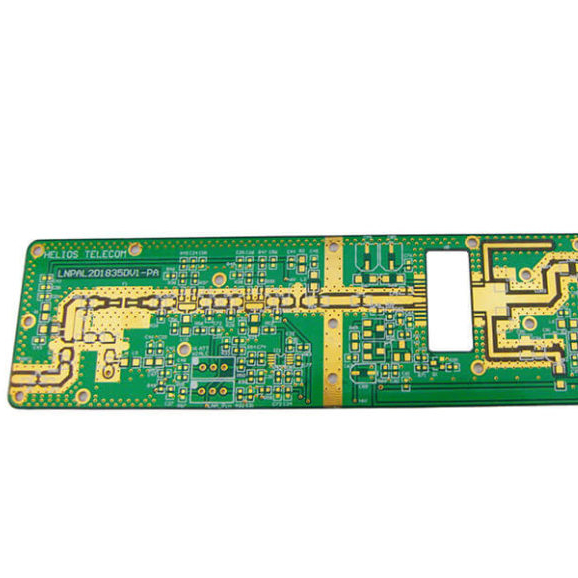

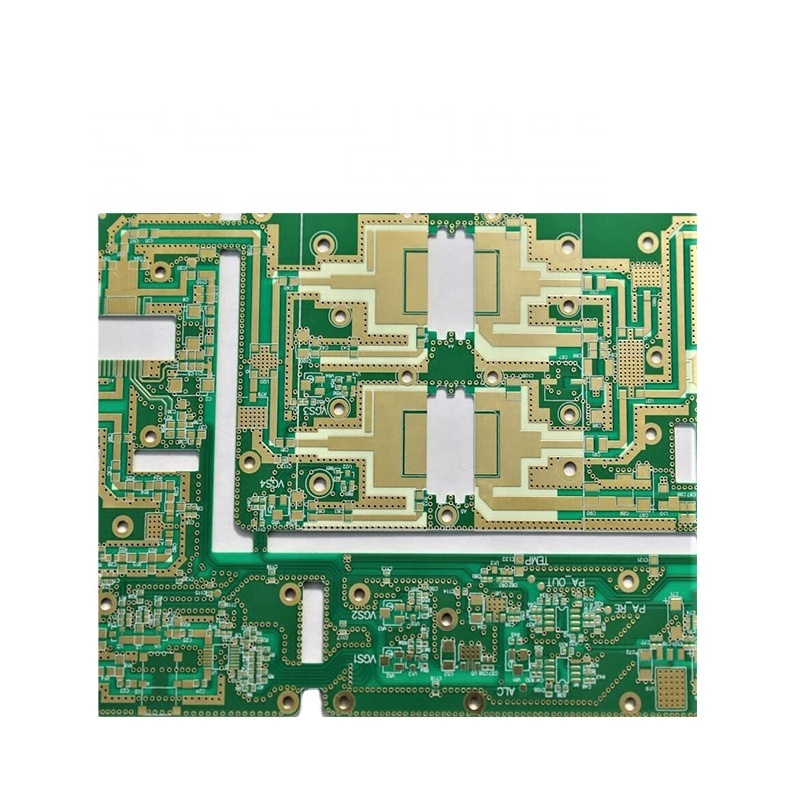

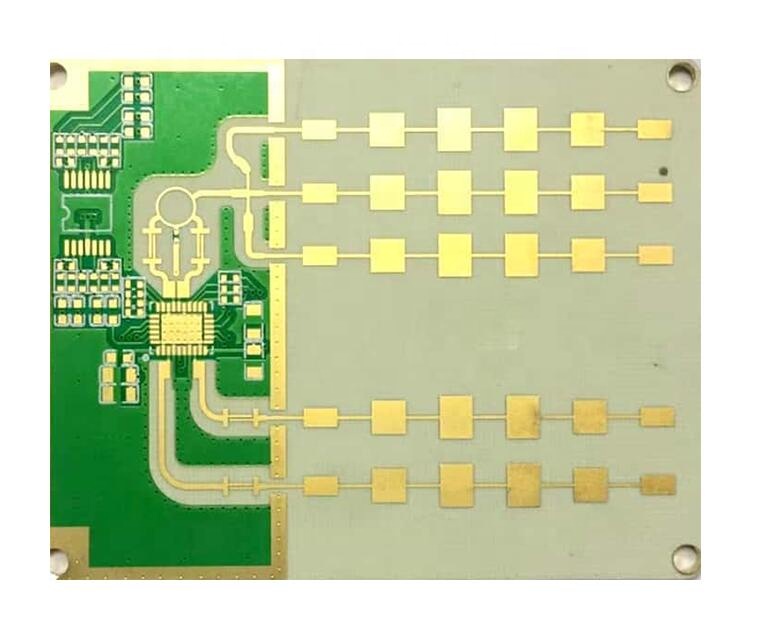

Microwave radio frequency board pcb

Basic Info

Model No.: RF/Microwave PCB

Product Description

Which metal is better for a printed circuit board?

The metal material-based printed circuit board is a composite printed circuit board made of a metal material-based steel plate, an insulating layer material layer, and a route copper layer. The metal material base is generally aluminum, iron, copper, indium copper, tungsten-molybdenum aluminum alloy and Other insulating layers. The material layer is commonly modified Epoxy Resin, polyphenylene ether, polyimide, etc., while the route layer is a copper layer, etc. constitute. Same as Rigid-Flex Board, the metal material-based printed circuit board can also be divided into single and double-sided PCB, double-sided PCB and double-layer PCB, which is a unique type of printed circuit board.

Because metal material-based printed circuit boards have excellent heat conduction (dissipation), magnetic shielding materials, and stable specifications. In recent years, they have become more and more common in communication power supplies, cars, motorcycles, motors, household appliances, and computer applications. The use of. The metal material-based printed circuit board has the following characteristics

(1) Heat dissipation of heat pipe

(1) Heat dissipation of heat pipe

At this stage, many HDI PCBs have high relative density and high output power, which require heat pipes to dissipate heat. The basic printed circuit board plates are usually all hot, poor conductors, and the insulation layer of the virtual beam cannot release the heat. All kinds of electronic products, switching power supply equipment, internal heat generation can not be removed, causing Electronic Components to become invalid quickly, and metal material-based printed circuit boards can handle the heat dissipation difficulties of this type of heat pipe. Many electronic products and communication equipment use metal material-based printed circuit boards. The fans in the machinery and equipment have been removed, the volume of the machinery and equipment has been greatly reduced, and the efficiency has been improved.

(2) Thermal deformation

Thermal expansion and contraction are the differences in the nature of chemical substances. The thermal expansion coefficients of chemical substances are different. The printed circuit board is a composite of epoxy resin, improved raw materials, and copper foil removal. The thermal expansion coefficient CTE of the printed circuit board in the XY axis direction is (13~18)×10°C, and the board thickness Z axis direction is (80~90×1010-6°C, while the CTE of copper is 168105°C. The CE of the shape of the porcelain body is 6×10°/℃. It is possible to see the metalized hole edge of the printed circuit board and the adjacent insulating layer wall in the Z-axis CTE caused by the large distance. Shrinkage will cause the metallized holes to crack or break, so that electronic products are unreliable.

Surface-Mount (SMT) & BGA Assembly makes this problem even more prominent. Because the interconnection of surface-mounted electronic devices is based on the surface spot welding and immediately connected to maintain the plasmid carrier of the porcelain integrated IC, the CTE is 6. The CIE of the FR4 sheet in the X-Y direction on the surface is (1318)X10°C, so the spot welding of the patch connection will cause fatigue and cracking due to the long-term ground stress due to the different CIE. The specifications of printed circuit boards based on metal materials change with temperature much more smoothly than those of printed circuit boards made of insulating layer materials. Aluminum-based printed circuit boards and aluminum color steel sandwich panels are heated from 30°C to 140~150°C, and the specifications are changed to 2.5%~3.0%.

Surface-Mount (SMT) & BGA Assembly makes this problem even more prominent. Because the interconnection of surface-mounted electronic devices is based on the surface spot welding and immediately connected to maintain the plasmid carrier of the porcelain integrated IC, the CTE is 6. The CIE of the FR4 sheet in the X-Y direction on the surface is (1318)X10°C, so the spot welding of the patch connection will cause fatigue and cracking due to the long-term ground stress due to the different CIE. The specifications of printed circuit boards based on metal materials change with temperature much more smoothly than those of printed circuit boards made of insulating layer materials. Aluminum-based printed circuit boards and aluminum color steel sandwich panels are heated from 30°C to 140~150°C, and the specifications are changed to 2.5%~3.0%.

In addition, metal material-based printed circuit boards, such as Aluminum base board, have the shielding effect and can replace heat pipe radiators and other components. Really and reasonably reduce the total area of the printed circuit board and low cost pcb manufacturing.

Common metal material base steel plates are:

1) The base heat transfer is good in areas where heat conduction and magnetic shielding materials are used, but the net is expensive.

2) The iron-based anti-interference signal shielding feature is optimized, but the heat pipe heat dissipation is slightly weaker and the price is low

3) Aluminum base board has good heat but not heavy and light magnetic shielding material is also very good.

Contact us if you need more details on Microwave RF Printed Circuit Boards. We are ready to answer your questions on packaging, logistics, certification or any other aspects about RF Microwave Printed Circuit Boards、RF Microwave PCB. If these products fail to match your need, please contact us and we would like to provide relevant information. Because metal material-based printed circuit boards have excellent heat conduction (dissipation), magnetic shielding materials, and stable specifications. In recent years, they have become more and more common in communication power supplies, cars, motorcycles, motors, household appliances, and computer applications. The use of. The metal material-based printed circuit board has the following characteristics

At this stage, many HDI PCBs have high relative density and high output power, which require heat pipes to dissipate heat. The basic printed circuit board plates are usually all hot, poor conductors, and the insulation layer of the virtual beam cannot release the heat. All kinds of electronic products, switching power supply equipment, internal heat generation can not be removed, causing Electronic Components to become invalid quickly, and metal material-based printed circuit boards can handle the heat dissipation difficulties of this type of heat pipe. Many electronic products and communication equipment use metal material-based printed circuit boards. The fans in the machinery and equipment have been removed, the volume of the machinery and equipment has been greatly reduced, and the efficiency has been improved.

(2) Thermal deformation

Thermal expansion and contraction are the differences in the nature of chemical substances. The thermal expansion coefficients of chemical substances are different. The printed circuit board is a composite of epoxy resin, improved raw materials, and copper foil removal. The thermal expansion coefficient CTE of the printed circuit board in the XY axis direction is (13~18)×10°C, and the board thickness Z axis direction is (80~90×1010-6°C, while the CTE of copper is 168105°C. The CE of the shape of the porcelain body is 6×10°/℃. It is possible to see the metalized hole edge of the printed circuit board and the adjacent insulating layer wall in the Z-axis CTE caused by the large distance. Shrinkage will cause the metallized holes to crack or break, so that electronic products are unreliable.

In addition, metal material-based printed circuit boards, such as Aluminum base board, have the shielding effect and can replace heat pipe radiators and other components. Really and reasonably reduce the total area of the printed circuit board and low cost pcb manufacturing.

Common metal material base steel plates are:

1) The base heat transfer is good in areas where heat conduction and magnetic shielding materials are used, but the net is expensive.

2) The iron-based anti-interference signal shielding feature is optimized, but the heat pipe heat dissipation is slightly weaker and the price is low

3) Aluminum base board has good heat but not heavy and light magnetic shielding material is also very good.

Product Categories : PCB Assembly Products > Through-Hole Assembly