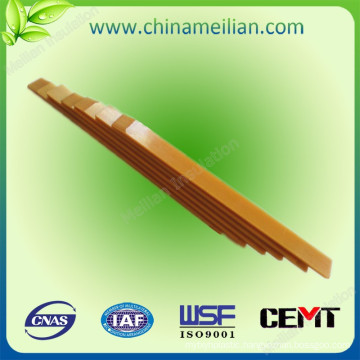

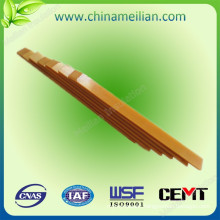

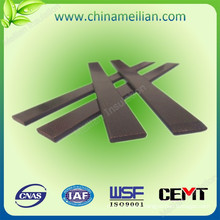

G11 Insulation Laminate Fiberglass Slot Wedge for Motor (Grade F)

Basic Info

Model No.: MJ-G11

Product Description

Model NO.: MJ-G11 Type: Insulation Sheet Material: Fiberglass Maximum Voltage: >100KV Certification: ISO9001 Brand: Mj Trademark: MJ Origin: Xi′an China Application: Insulators, Electrical Winding Insulation, Winding Wire Coating Insulation, Electrical Base, Shell, Motor, Insulating Varnish, Switch Baseplate, Transformer Chemistry: Inorganic Insulation Thermal Rating: F 155 Classification: Inorganic Insulation Material Color: Brown Size: According to Customer Requirement Specification: ISO9001 HS Code: 85479090 Appearance:

Natural color Orange, surface smoothly without bubble and impurities, no flow marks, Cutting edge without fault and separation

Feature:

Excellent mechanical & electric property

Good heat & moisture resistance

Easy for processing & machining & installing

Application:

Motors & generators

Traction motors

High-speed motors

Wind turbines Metro reactors

Packaging Detail: Epoxy slot wedge package: Each package is not more than 100KG. Respectively, paper and plastic film cover plate, a paper packaging box, steel strapping / or according to customers' requirements.

Delivery Detail: 7-10 working days

FAQ:

(1) Can you give me a discount price?

Answer: It is depending on the volume. The larger the volume is, the more discount you can enjoy.

(2) Why is your price a bit higher than Other Chinese suppliers?

Answer: To meet the requirement of different customers and areas, our factory manufactures various kinds of quality for each item at a wide range of price. We can offer the products of different quality levels depending on customer's target price and quality requirement.

(3) How can I get a sample?

Answer: Normally small samples (sizes not larger than 300*300mm) can be sent free of charge and customers just need to bear a little shipping charge, or you can provide your DHL, FEDEX, EMS, UPS courier account number to us. For bigger sizes, it depends.

(4) How can you guarantee the quality of mass production is same with the sample sent to me before?

Answer: Our warehouse staff will leave another same sample in our company, with your company name marked on it, which our production will be based on.

(5) How can you deal with quality issues that customer feedback after receiving the goods?

Answer:

1) Customers take photos of unqualified goods and then our sales staff will send them to Engineering Department to verify.

2) If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in coming orders.

3) Finally, we will negotiate with our customers to make some compensation.

Natural color Orange, surface smoothly without bubble and impurities, no flow marks, Cutting edge without fault and separation

Feature:

Excellent mechanical & electric property

Good heat & moisture resistance

Easy for processing & machining & installing

Application:

Motors & generators

Traction motors

High-speed motors

Wind turbines Metro reactors

Packaging Detail: Epoxy slot wedge package: Each package is not more than 100KG. Respectively, paper and plastic film cover plate, a paper packaging box, steel strapping / or according to customers' requirements.

Delivery Detail: 7-10 working days

FAQ:

(1) Can you give me a discount price?

Answer: It is depending on the volume. The larger the volume is, the more discount you can enjoy.

(2) Why is your price a bit higher than Other Chinese suppliers?

Answer: To meet the requirement of different customers and areas, our factory manufactures various kinds of quality for each item at a wide range of price. We can offer the products of different quality levels depending on customer's target price and quality requirement.

(3) How can I get a sample?

Answer: Normally small samples (sizes not larger than 300*300mm) can be sent free of charge and customers just need to bear a little shipping charge, or you can provide your DHL, FEDEX, EMS, UPS courier account number to us. For bigger sizes, it depends.

(4) How can you guarantee the quality of mass production is same with the sample sent to me before?

Answer: Our warehouse staff will leave another same sample in our company, with your company name marked on it, which our production will be based on.

(5) How can you deal with quality issues that customer feedback after receiving the goods?

Answer:

1) Customers take photos of unqualified goods and then our sales staff will send them to Engineering Department to verify.

2) If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in coming orders.

3) Finally, we will negotiate with our customers to make some compensation.

| Basic information | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Product name | Electrical Insulation Stator Wedge | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Item No. | With the same item numbers of the laminates which used for processing | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Brand | MJ | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Material | Epoxy Resin and Alkali free fiberglass cloth | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Grade | Grade F | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical Performance | |||||||||||||||||||||||||||||||||||||||||||||||||||

| Density | ≥1.7g/cm 3 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Sheets Thickness | 0.1-50mm | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Size | Customized | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Formation methods | High temperature and high pressure | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal stability in 24h | ≥180

at room temperature at high temperature 180±2°C ≥400 MPa ≥340 MPa Insulation Resistance after immersion in water (D-24/23) 5.1×10 8 W Dielectric Strength perpendicular to laminations (in 90±2 °C transformer oil, 1 mm) 10.4 KV/mm Voltage resistance parallel to layer (at 90°C±2°C oil for 1min) ≥35 kV Breakdown Voltage parallel to laminations (in 90±2°C transformer oil) ≥40 kV Permittivity (50Hz) 5 Permittivity (1MHz) 5.1 Dissipation Factor (50Hz) 0.05 Dissipation Factor (1MHz) 0.03 Reference Standard GB/T1303.1-1998 Contact us if you need more details on Motor Slot Wedges by Epoxy Glass. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Motor Insulation Strip、Epoxy Slot Wedge. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Epoxy Stator Slot Wedge Other Products

Hot Products 9334 Polyimide Electrical Insulation PrepregEpoxide Glassfiber Mica Paper TapePVC Fiberglass Cable Insulation SleevesAluminum Based Copper Clad Laminated SheetSilicone Fiberglass Tube Epoxy ResinAcrylic Coated Fibreglass SleeveSilicone Rubber SleevingHeat Shrink TubeHot Sales Fire-Resistant Mica Roll (C)Thermal Expansion Pad/ Stips/Pad for MotorHigh Quality Insulation Impregnating VarnishFactory Wholesale Fireproof Thermal Insulation Board (MJ-301)Hot Sales Epoxy Mica Tape (C)G10 Epoxy Motor Slot Wedges (B)Magnetic Electrical Insulation Laminated Sheet (B-F)347 Epoxy Fiberglass Insulation Press Board | ||||||||||||||||||||||||||||||||||||||||||||||||||